India International Water Week - Climate Resilient Water Management Event Description Although nearly 70% of the Earth&...

Examining the Pros and Cons of Fog Cannon Dust Suppression

An industrial fog is generated from a powerful fan or nozzle that sprays dust suppressants to bind dust particles together. The fogging process includes releasing nozzles that convert water into very small micro-droplets under pressure, which helps push airborne dust particles to the ground and wets its surface to avoid any loose particles. Water atomized mist created has an average size range, sometimes smaller than 10 microns. When mixed with airborne dust, the surface of the water molecules provide an adhesive effect; after condensing due to gravity, it can achieve dust suppression. Therefore, fog cannon machines are perfect for construction areas where they can reduce demolition dust, urban development zones, coal storage yards, mining sites, and ports, as their primary function is spray dust suppression.

Fog cannon machines are helpful in dispersing dust particles, breaking down high salt concentrations in the air, and reducing airborne pollutants.

This article discusses

Investigating the technology of fog cannon dust removal What are the elements of a fog cannon dust suppression system? Analyzing its pros and cons, How it is used in various industries

Understanding fog cannon dust control technology.

The fundamental premise for fog cannon dust suppression is known as the Slipstream Effect. The dust particle must be on equal footing compared to the droplet of dust suppressant to bring them together in the air and direct it to the ground. The risk is higher than this dust particle will then crash with the droplet and become absorbed, bringing the dust down to ground level.

Having few droplets of dust suppressant and ample water means outstanding coverage. Because tiny droplets present a better ratio of surface area to mass, they have more significant air pressure facing gravity, making them buoy lighter when compared with their heavier counterparts before gravity affects them. This science states that more massive water droplets are affected by gravity much sooner than clouds—whereby overly large water droplets fall as rain. Smaller drops tend to evaporate more quickly, which is why you might need an adapted nozzle, depending on your circumstances. Sometimes, it could be the desired result based on your particular needs. Tiny water droplets create a thick fog that captures dust particles, increasing their weight and causing them to drift from the air around them. Plus, this fog cloud has to be thicker than concentrations of dust particles so that all these particles can be grabbed up.

What makes up a fog cannon dust suppression system?

Nozzle: breaks down the water into tiny water mist particles, which help to reduce dust more quickly and create a consistent spray pattern. Water pump: The dust removal fog gun's core component transports water from the tank to the nozzle and sprays it with high pressure. The fan produces fast-moving air. When the fan blade rotates, it sends out a strong airflow via the nozzle, which atomizes fine droplets and directs them to wherever they're needed.

Centrifugal fans with easy operation, high air pressure, high velocity, and powerful air penetration are typically used. They have backward curved blades, which ensures a better total pressure efficiency and increases spray area - thus improving the atomization effect.

The output of the air pipe is capable of rotating 360° in the horizontal plane (usually at 350° when used) to adapt to changes in direction, as well as a steering positioning device to adjust the height angle of release.

Know the pros and cons of using fog cannons for dust suppression

When looking at the benefits of fog cannon dust control, the critical criteria are reducing water volume used from the dust suppression system and removing residue. The advantages mainly depend on what it's being applied to.

Are you worried about environmental regulations, health and safety risks, or possible financial losses?

Fog cannon systems allow you to use water more efficiently and cost-effectively. Stormwater effects and runoff are reduced, which helps keep the air and land clean, plus there are fewer standing bodies of water to create a safer worksite. Compared to fog cannons which make dust suppression with lower saturation levels, they create a muck that clings onto surfaces and equipment, reducing the lifespan of them both. Dust suppression using fog cannon reduces labor costs with automated operation. You can plug, play and forget about it!

Fog cannon dust suppression is gaining traction as one of the favorite solutions for dampening dust. Water flow rates can be adjusted to regulate water discharge from the fog, resulting in better control of surface and airborne dust without worrying about saturation. The cannon can be installed in either a stationary or a movable position, depending on the requirements of the particular location. They are highly efficient, and implementation is quick and easy. These long-term solutions can provide years of hassle-free functioning with regular upkeep.

Fog cannons have their limitations -

Initially, lack of coverage can be attributed to evaporation. Despite their advantages, foggers require a still and calm environment to be effective. The fog needs to linger in the air undisturbed, so it can gradually attach itself to dust particles.

In cases where the dust particles are hydrophobic, fogging systems will act as a barrier rather than remove the dust from the air. However, this can be improved with technologies such as GRT: Activate for more effective dust control.

What are the uses of the fog cannon dust suppression system?

Dust suppression systems with fog cannons are designed to address the dust particles floating in the air that originates from mining activities, demolition sites, and bulk material handling sites. Cloud seeding machines come in various sizes; compact models are perfect for stifling blowing dust that occurs at precise points, such as when unloaded onto piles, loaded into ships, taken off piles, dropped, crushed, and loaded/unloaded on trucks. Aimed towards the source of the dust, they immediately suppress whatever is released before it can spread. Compared to other models, their water use is minimal. The larger versions are adept at controlling general airborne dust by fogging a large area. When combating high-amount events like blasting, the low throw distance essential makes them quite helpful. The range comes from 30 to 500 meters, and powerful fans are necessary for operation. From 0-45 degrees is adjustable elevation along with full automatic 360-degree rotation, and water consumption fluctuates from 15 liters/min to 6000 liters/min based on model and use. To further strengthen spray efficiency, liquid polymers or surfactants in chemical form can be added as dust-suppressing agents or make water more effective or result in layers on stockpiles, respectively. Additionally, various fog cannon systems offer extras such as remote control outfits, including cameras, explosives-resistant versions, and vehicle-inclusive self-packing systems with elevated telescopic sections.

Dust management

The fog cannon dispenses a mist from water that efficiently suppresses flying dust particles. Binding the dirt to its source helps protect lives since dust is hazardous. If not managed correctly, dust may noticeably lower productivity, substantially bump up operational costs, ruin the environment, and potentially threaten the safety of workers and nearby communities. GRT supports using dust suppression to minimize risks to miners, laborers, and communities close by sites with powder-producing operations.

If you are running a restaurant, it is important for you to adhere to the local municipal rules. Restaurants must en...

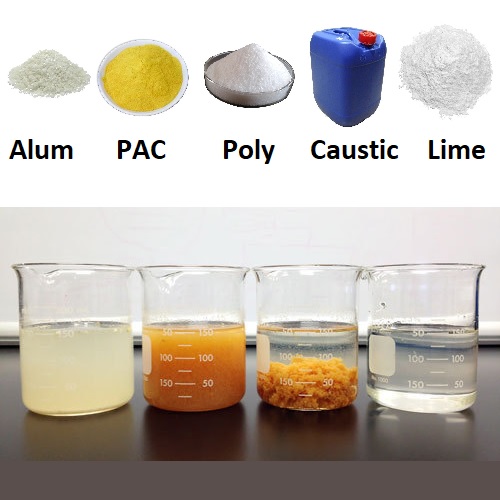

Commercial Kitchens, those in hotels, food courts, and restaurants, generate a high volume of Fats, Oils and Grease (FOG).&nb...

Are you planning to invest in a grease trap for your food facility? If so, you will want to understand the grease trap price....

Whether you are running a big restaurant or a 50-seat commercial kitchen, it is important to choose the right grease trap siz...

Air Pollution in many Indian cities, including the national capital, is increasing at an alarming rate. Many people ...

If you are running a commercial kitchen in India, whether it is a restaurant, hotel, food court, or cloud kitchen, beyond goo...