India International Water Week - Climate Resilient Water Management Event Description Although nearly 70% of the Earth&...

What is an ETP plant and how does it work?

Effluent Treatment plant are used by many companies to clean water and remove any toxic and non-toxic materials, chemicals from it so that water can be reused or released in the environment so that there will be less harm to the environment.

Function of ETP plant- ETP plant treat waste water. All the industries including pharmaceutical, chemical, textile and others generate waste water and they use ETP plant to remove any toxic material or chemicals from water and generate pure water for reuse.

The approach of treatment includes the removal of the suspended particles, dissolved organic matters and handling of sludge for disposal.

How does ETP plant works?

There are various processes involved in cleaning the contaminated water of the industries through ETP plant and that includes-

1. Equalization: The waste water is collected in an existing mixed effluent tank and pumped to an existing aeration tank that also functions as an equalization tank. The effluent is homogenized by the floating aerator before being pumped to the neutralization tank for treatment.

2. pH control: pH neutralization is used to change the pH water levels as the pH value of the effluent should be between 5.5 and 9.0. For acidic solutions bases are used to modify the pH and for alkaline waste, acids are used.

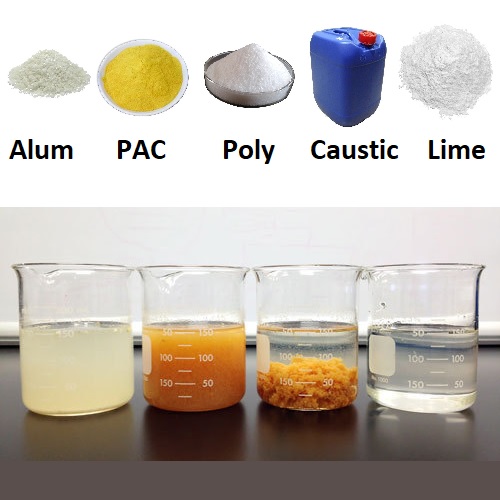

3. Coagulation: Here liquid aluminum sulphate is added to the untreated water. This causes tiny dirt particles to stick together after mixing. This collection of particles blends together to generate large heavier particles that are removed easily via settling and filtration.

4. Sedimentation: In this process water travels slowly causing the heavy particles to settle at the bottom. Sludge is the term for particles that gather at bottom of container.

5. Filtration: It is the process of passing water through the filter that removes particles. The filters are made out of sand and gravel layers. These filters are to be regularly cleaned via backwashing.

6. Disinfection: Water is disinfected before entering the distribution system using chlorine.

7. Sludge drying: Sediments collects and settles down solids that are then transported to drying beds. The sludge when it reaches around 300 mm, it sludge charging needs to be stopped and the bed should be segregated to allow natural evaporation to dry if off.

Benefits of ETP plant-

• Cleans industry effluent and recycle it for further use.

• Reduce usage of fresh water in industries

• Preserve natural environment against pollution

• Meet the standards for emission of pollutants set by the Government to avoid fines.

Is your industry polluting? ETP plant can Help!

Industrial effluents contain various materials as per industry. Some effluents contain grease and oil and some contain toxic metals. Effluents from food and beverage factories contain degradable organic pollutants. As industrial waste water contains a diversity of impurities and so specific treatment called ETP is required.

ETP plant works at various levels and involves varied physical, chemical, biological and membrane processes to treat waste water from varied sectors including chemicals, pharmaceuticals, refineries, dairy, drugs and more.

Also Read Recent Blog:-

Who is eligible to apply for DPCC online?

If you are running a restaurant, it is important for you to adhere to the local municipal rules. Restaurants must en...

Commercial Kitchens, those in hotels, food courts, and restaurants, generate a high volume of Fats, Oils and Grease (FOG).&nb...

Are you planning to invest in a grease trap for your food facility? If so, you will want to understand the grease trap price....

Whether you are running a big restaurant or a 50-seat commercial kitchen, it is important to choose the right grease trap siz...

Air Pollution in many Indian cities, including the national capital, is increasing at an alarming rate. Many people ...

If you are running a commercial kitchen in India, whether it is a restaurant, hotel, food court, or cloud kitchen, beyond goo...